Blue Tube 2.0

What Is It?

Blue Tube is rocket airframe material borne from the most unusual source, TANK AMMUNITION! In conjunction with Phenix Tube, Blue Tube 2.0 is the creation of Always Ready Rocketry, and is only available from ARR or an authorized dealer. It is highly abrasion resistant, with massive acceleration potential for a spiral wound product. Blue Tube 2.0 is also Mach capable right out of the box. This airframe is able to withstand g-forces that exceed 10x anything any high-power rocket flight can present to it. No glassing necessary, no huge gaps to fill, no prepping, no sanding, no nothing, and most of all, COMPATIBLE with existing components!

Where Did It Come From?

Blue Tube 2.0 is manufactured exclusively under contract for Always Ready Rocketry, LLC by Precision Products Group International. This material is ALREADY in use as a component in a military weapon that exposes it to an environment where acceleration exceeds 1000g’s, as a component inside a warhead of the 155mm Howitzer, and 105mm Abrams Tank ordinance.Blue Tube 2.0 is 28% more dense than phenolic (because it’s NOT phenolic) and 36% lighter than fiberglass. There is no question that carbon fiber and filament wound fiberglass is the ultimate in airframes, but, who can afford it? Why bother when you can have something that is easier to work with and able to take a ride down the barrel of a tank, and 40% cheaper.

Blue Tube 2.0 is manufactured exclusively under contract for Always Ready Rocketry, LLC by Precision Products Group International. This material is ALREADY in use as a component in a military weapon that exposes it to an environment where acceleration exceeds 1000g’s, as a component inside a warhead of the 155mm Howitzer, and 105mm Abrams Tank ordinance.Blue Tube 2.0 is 28% more dense than phenolic (because it’s NOT phenolic) and 36% lighter than fiberglass. There is no question that carbon fiber and filament wound fiberglass is the ultimate in airframes, but, who can afford it? Why bother when you can have something that is easier to work with and able to take a ride down the barrel of a tank, and 40% cheaper.

How Can We Make These Claims?

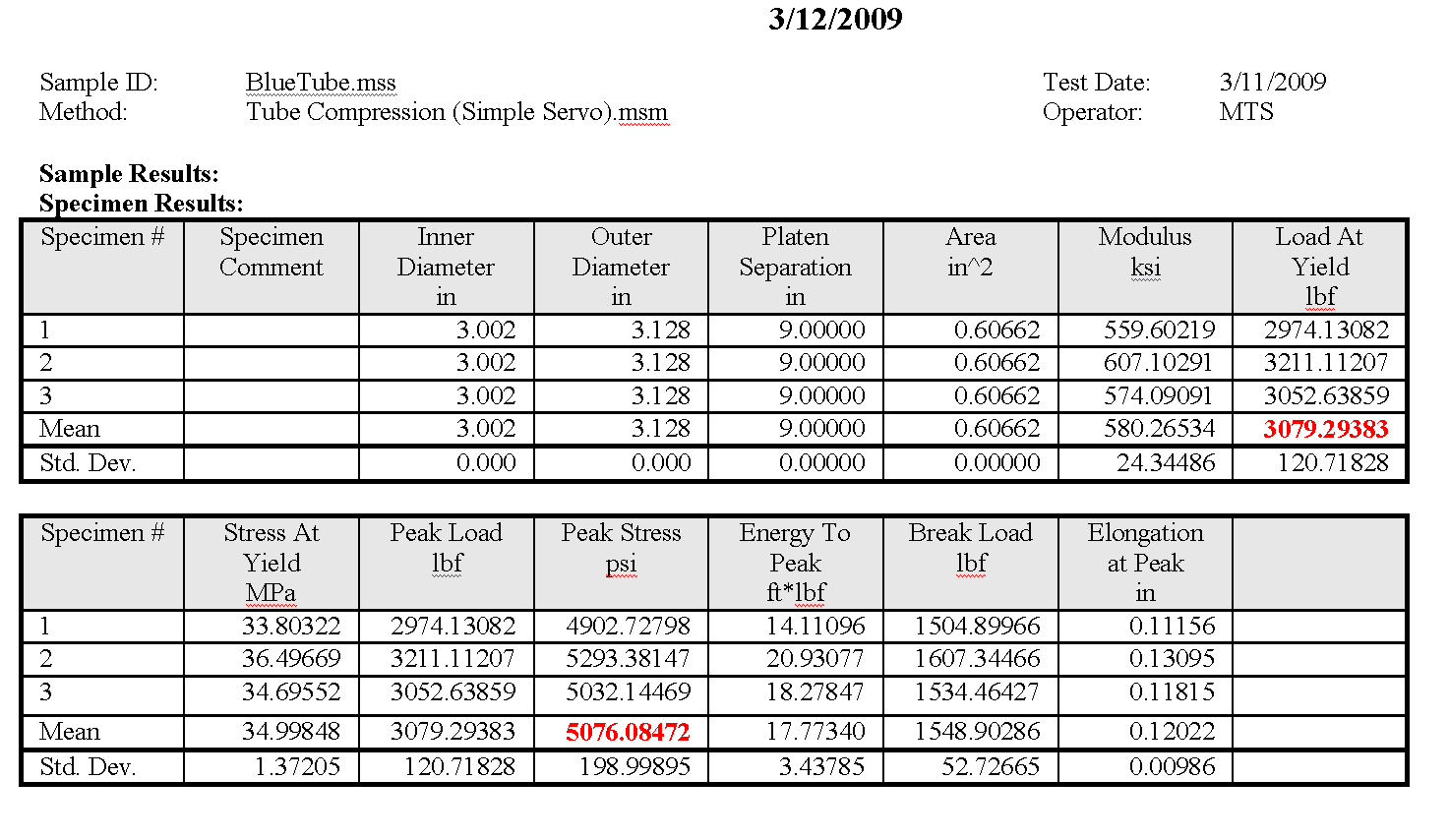

Dr. Drake Dämerau, while working in the testing facility at General Dynamics, tested three 3 inch diameter 9 inch long samples and has confirmed that Blue Tube’s axial peak stress was about 2.6 tons and was not prone to shatter or crack like fully cured phenolic. Drake said “Tough stuff! It didn’t break like phenolic does. Gives a lot more under stress.”

Download the 3M Engineering Data Sheet

Download the Vulcanized Fibre Material Safety Data Sheet

What Does All This Mean?

Why is this important?

If you buy Blue Tube for your next project, you get far more abrasion resistance, zero cracking, zero brittleness, far more strength than partially cured phenolic, and far more radial strength than all three! Has this ever happened to you? You built an awesome high-power rocket using phenolic tubes, and it performs flawlessly. But then, the rocket starts to sway a little bit as it descends under the parachute. When it touches down on the ground, it lands on a fin tip. The full landing load travels up the fin and is transferred right up to the tube of the rocket, cracking the tube. The tube isn’t bent or creased, it is cracked! The horror stories of cracked or shattered phenolic tubes are numerous. That is the reason that everyone puts a layer or two of fiberglass over the top of them.Covering an airframe with fiberglass is a mess. You spend twice as much time strengthening the tube and the stink and resin mess is everywhere. You begin to wonder if it is worth it. Once you put fiberglass over the tube, you have to take precautions not to breathe the dust as you sand down the tube. If you have children in your house, you have to send them outside while you’re exercising your muscles sanding down the fiberglass.Using Blue Tube 2.0 makes it unnecessary to shockproof your airframe with fiberglass and it costs less than those expensive carbon fiber tubes.Ideally you want a material that has the strength of phenolic, without the brittleness of phenolic. Blue Tube 2.0 is what you have been looking for.

Exceptionally durable, as the photos show, even hitting Blue Tube with a golf club shows some denting, but for the most part, the tube is still usable for your rockets. If you hit a phenolic tube with a golf club, the game is over. The tube cracks or shatters. Blue Tube 2.0 has far more resistance to abrasion and has no cracking, or brittleness. This is the tubing you need for your next high-power rocket project!

The Care and Feeding Of Blue Tube 2.0

For best results, keep dry, rough up the surface with fine sandpaper and seal with a few coats of OIL BASED sanding sealer. Sand and paint as usual. Sanding sealer is a thin penetrating liquid for wood. It will wet the vulcanized fiber, soak in and dry. This will make a vapor barrier and a great base to paint on. No primer is necessary. Sand lightly until smooth. That’s it!

Blue Tube 2.0 Is:

- More abrasion resistant than anything in its price class.

- Able to create a stronger bond to other component materials, due to Blue Tube 2.0’s superior adhesive absorption.

- More forgiving and impact resistant than anything in its price class.

- Mach capable out of the box.

- Radially stronger than anything in its price class.

- Nearly as strong as fully cured hard brittle phenolic without the problems.

- 36% lighter than fiberglass.

- Made from earth friendly materials.

If you plan on using any telemetry in your project, Blue Tube 2.0 is also Radiolucent (Transparent to radio waves) .

All diameters of Blue Tube 2.0 are produced in 48 inch lengths and are available thru ARR or an authorized dealer. The 5.5, 6.0 and 7.5 inch diameter tubes are also available in 72 inch lengths only on this website. Blue Tube 2.0 can be cut, sanded, and shaped with ordinary hand tools. Use the same eye and dust protection you would use when working with wood products.